Payments and Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Description

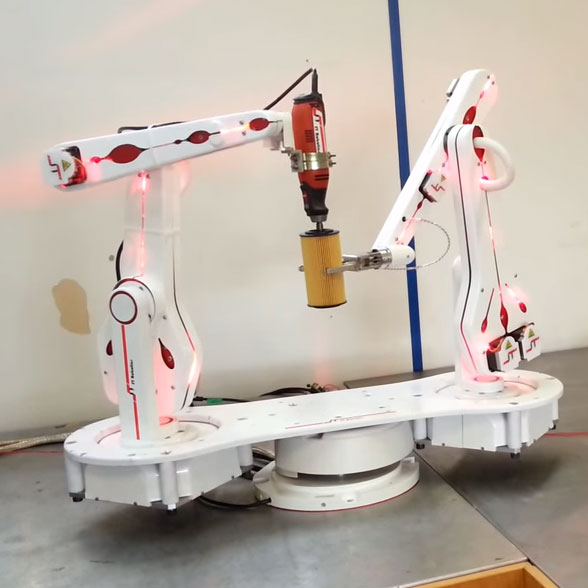

Specifications - standard 5 and 6 axis version

| Drives: | High power micro-stepped hybrid stepping motors incremental encoder watchdogs |

|

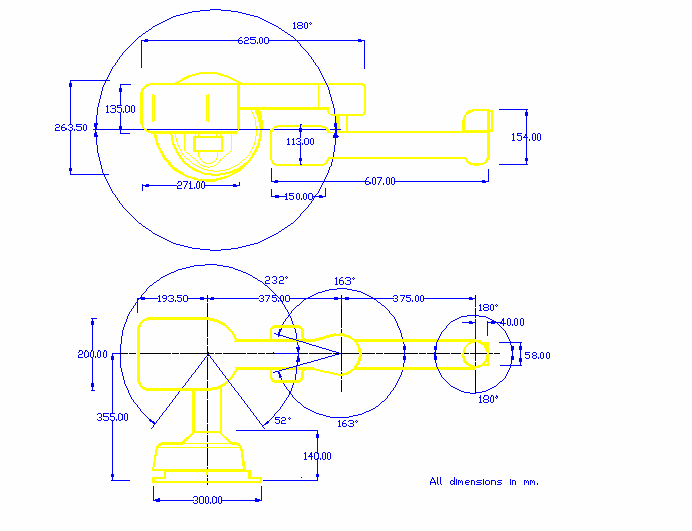

| Reach: | 750mm/30ins in any direction; full 360 degree waist rotation | |

| Payload (standard): | nominal 1Kg, max 3Kg (4.4lbs) at flange (repeatability and speed degrade with increasing payload and reach). |

|

| Repeatability: | 0.2mm (see note) | |

| Compliance: droop at 500mm at nominal payload: droop at max reach, max payload: |

1.0mm 6mm |

|

| Maximum speed (standard drives*): | Waist 150 deg/sec, Shoulder 90 deg/sec, Elbow 130deg/sec, hand and wrist 320deg/sec, 6th axis roll 330deg/sec. (approx 800mm/s) |

|

| Max torque for hand pitch or roll: (6th axis version hand pitch and yaw) |

2 Nm (repeatability figures degrade with increasing torque). | |

| Max torque for 6th axis roll: | 0.4 Nm | |

| Weight | 5-axis 22.0Kg/49lbs, 6-axis 23.0Kg/52lbs, Controller 11.1kg/25lbs | |

| Power: | 110/240v ac 420VA (standard controller) | |

| Environment: | IP 54A, 0 - 40C (wider range optional) | |

| MTBF: | 20,000 hours (typically over a million cycles) | |

|

Finish: |

White powder-coat plus white vacuum formed ABS plastic covers. |

Specifications - Higher Payload Version (contact us for a quote)

| Drives: | High torque micro-stepped hybrid stepping motors incremental encoder watchdogs |

|

| Reach: | 750mm/30ins in any direction; full 360 degree waist rotation | |

| Payload: | nominal 3Kg, max 5Kg at flange. (repeatability and speed degrade with increasing payload and reach). |

|

| Repeatability: | 0.2mm (see note) | |

| Compliance: droop at 500mm at nominal payload: droop at max reach, max payload: |

1.0mm 8mm |

|

| Maximum speed (standard drives*): | Waist 150 deg/sec, Shoulder 90 deg/sec, Elbow 130deg/sec, hand and wrist 320deg/sec. (approx 800mm/s) | |

| Max torque for hand pitch or roll: | 5 Nm. | |

| Weight | Robot 23.1Kg/52lbs, Controller 11.1kg/25lbs | |

| Power: | 110/240v ac 420VA (standard controller) | |

| Environment: | IP 54A, 0 - 40C (wider range optional) | |

| MTBF: | 20,000 hours (typically over a million cycles) | |

| Finish: | White powder-coat plus white vacuum formed ABS plastic covers. |

Specifications - Higher Speed Version (contact us for a quote)

| Drives: | State-of-the-art AC servos with hybrid stepping motors on axes 4+5 incremental encoder watchdogs |

|

| Reach: | 750mm/30ins in any direction; full 360 degree waist rotation | |

| Payload: | nominal 3Kg, max 5Kg at flange. (repeatability and speed degrade with increasing payload and reach). |

|

| Repeatability: | 0.2mm (see note) | |

| Compliance: droop at 500mm at nominal payload: |

1.0mm |

|

| Maximum speed: | Waist 300 deg/sec, Shoulder 180 deg/sec, Elbow 360deg/sec, hand and wrist 600deg/sec. | |

| Max torque for hand pitch or roll: | 10 Nm. | |

| Weight | Robot 22.5Kg/50lbs, Controller 11.1kg/25lbs | |

| Power: | 110/240v ac 420VA (standard controller) | |

| Environment: | IP 54A, 0 - 40C (wider range optional) | |

| MTBF: | 20,000 hours (typically over a million cycles) | |

| Finish: | White powder-coat plus white vacuum formed ABS plastic covers. |